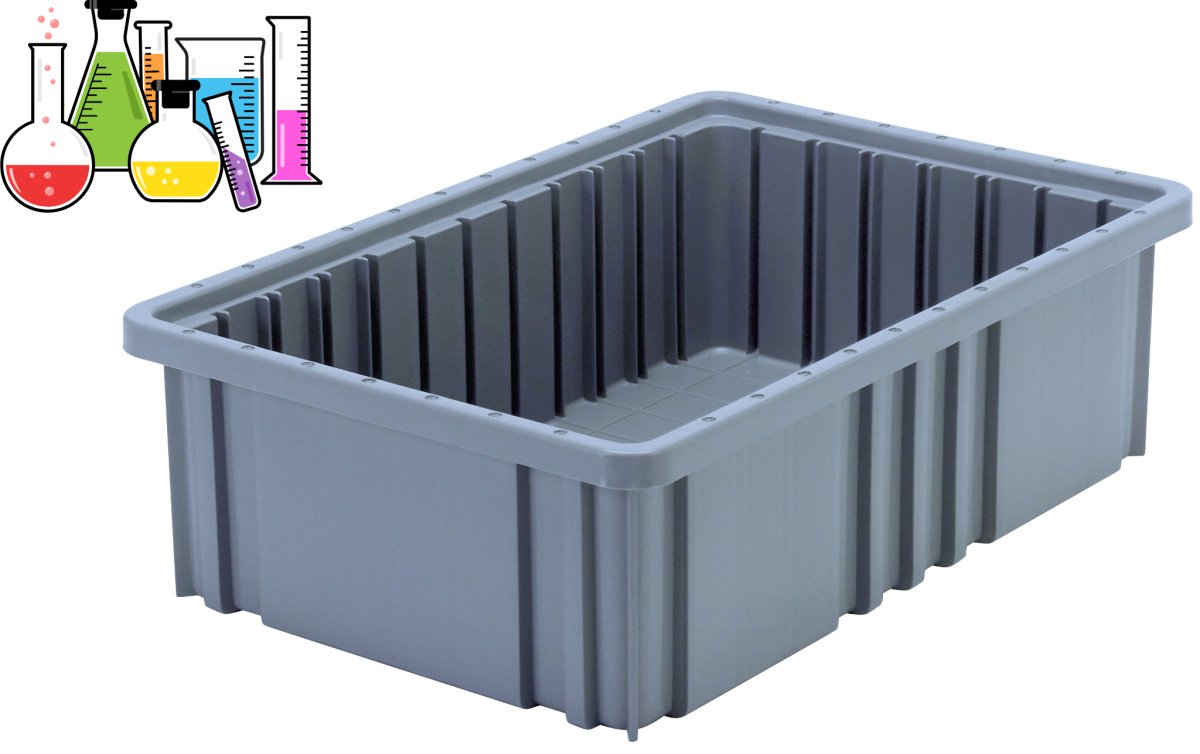

Maximizing Safety and Efficiency with Plastic Dividable Grid Containers

Introduction

Handling liquids and chemicals demands solutions that ensure efficiency, safety, and regulatory compliance. Plastic dividable grid containers provide a practical answer. This summary provides key points from our detailed post on plastic dividable grid containers, which offer efficient, safe, and compliant solutions for handling liquids and chemicals.

Key Features and Benefits

- Durability and Chemical Resistance: Made from high-density polypropylene, these dividable grid containers resist a wide range of chemicals and withstand significant wear.

- Customization: Adjustable compartments accommodate various container sizes, optimizing space and organization.

- Safety Features: Optional snap-on covers protect contents from dust, spills, and exposure to hazardous materials.

- Ease of Handling: Designed for stacking and easy transport, ideal for warehouses and production facilities.

Applications

- Pharmaceuticals: Used by companies like Pfizer and Merck for storing raw materials, clinical trial materials, and finished products, ensuring safety and regulatory compliance.

- Chemical Manufacturing: Utilized by BASF and Dow Chemical for segregating and safely transporting various chemicals.

- Food and Beverage Industry: Employed by Nestlé and Coca-Cola for ingredient storage, production line management, and compliance with food safety standards.

Conclusion

Plastic dividable grid containers enhance safety, efficiency, and compliance across multiple industries, making them indispensable for handling liquids and chemicals. Their versatile design and robust features meet the demanding needs of various sectors, from pharmaceuticals to food and beverage production.

For more detailed information, read the full blog post here