ESD-Safe Storage Bins, Containers, and Shelving Solutions at the Guaranteed Lowest Prices - with Free Shipping.

ESD Safe Divider Boxes

ESD Safe Stacking Bins

ESD Safe Nesting Shelf Bins

SMT Reel Wire Shelving Carts

View detailsComplete ESD Protection for Sensitive Components

Standard storage is a gamble; ESD-safe storage is a guarantee. Different electronic components have different sensitivity levels to electrostatic discharge. Our container systems are engineered to meet the storage requirements of the most fragile semiconductor devices, including:

- MOSFETs & CMOS Logic: These voltage-driven components are highly susceptible to gate oxide damage. Our conductive bins provide the Faraday Cage effect necessary to shield them from external static fields.

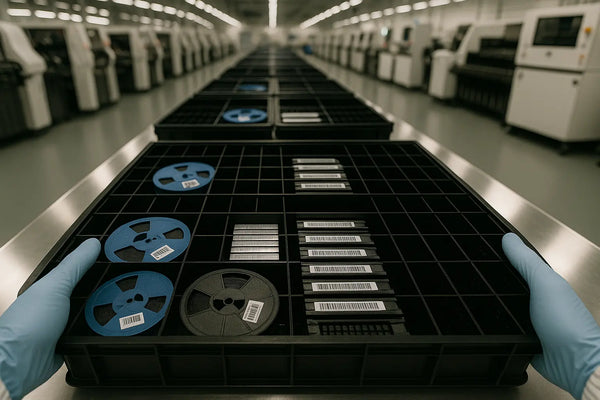

- Surface Mount Technology (SMT) Reels: Loose reels are a compliance nightmare. Our SMT Reel Shelving and wire baskets ensure reels remain upright, organized, and grounded, preventing the "triboelectric charging" that occurs when plastic reels slide against standard shelving.

- Printed Circuit Boards (PCBs): Whether raw or populated, PCBs require ESD-Safe Divider Boxes to prevent board-to-board contact and physical shock during transport.

- Data Storage (HDDs & SSDs): For data centers and server maintenance, our antistatic totes provide a secure environment for hard drives, protecting sensitive read/write heads and flash memory controllers from latent static damage.

Deep Dive: Conductive vs. Static Dissipative Storage

One of the most common questions we receive from facility managers is: "What is the difference between conductive and static dissipative bins, and which one do I need?"

1. Conductive Storage (Black)

- How it works: These bins have a low electrical resistance (typically < 10^5 ohms). They allow static charges to flow quickly across the surface to ground.

- Best for: Most industrial electronics manufacturing, PCB assembly, and protecting extremely sensitive parts (like MOSFETs) because they create a "Faraday Cage" that blocks external static fields.

- Our Products: The majority of the black bins in this collection are permanently conductive carbon-loaded polypropylene.

2. Static Dissipative Storage (Blue/Gray/Pink)

- How it works: These materials have a higher resistance (typically 10^6 to 10^11 ohms). They allow static charges to flow to ground more slowly and in a controlled manner.

- Best for: Cleanrooms or environments where a rapid discharge (spark) could be dangerous, or for automated handling trays where you want to prevent sudden "zaps" to a charged device.

Industry-Specific Applications

For Hyperscale Data Centers

As detailed in our case study on Tech Giants like Amazon and Google, uptime is the only metric that matters. Replacing a fried motherboard or corrupt SSD due to static discharge is an avoidable expense. Our stackable ESD totes and wire shelving are standard issue in server maintenance rooms, allowing technicians to swap parts safely without risking the integrity of the cloud infrastructure.

For Electronics Manufacturing & Assembly

In high-volume manufacturing, "latent defects" are the enemy. A component damaged by static might pass the factory test but fail a month later in the customer's hands. By implementing a full ESD-safe bin system—from the receiving dock to the assembly line—you eliminate the most common cause of early product failure.

Frequently Asked Questions About ESD Storage

Can I just use regular plastic bins with an antistatic spray?

No. Topical sprays are temporary and can wear off or vaporize, leaving your expensive components vulnerable without you knowing. Our bins are made from conductive polypropylene, meaning the ESD protection is intrinsic to the material and will last for the lifetime of the product.

Do these bins require grounding?

For maximum protection, yes. Conductive bins work best when placed on grounded wire shelving or conductive workbenches. This creates a complete path to ground, ensuring that any static charge is immediately and safely removed from your inventory.

Are these bins suitable for Cleanrooms?

Yes. Many of our ESD-safe containers are designed for low particle generation and are suitable for cleanroom environments used in semiconductor fabrication and medical device manufacturing.