Epoxy Coated Wire Shelving

46 products

Showing 1 - 36 of 46 products

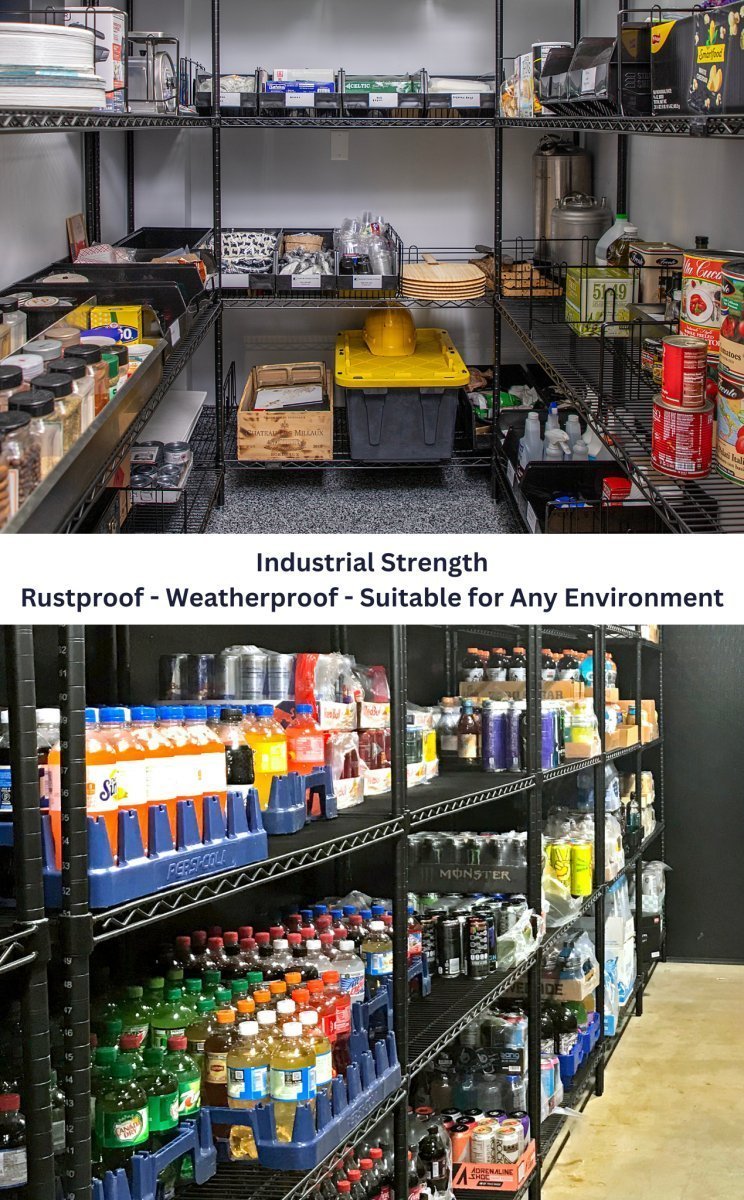

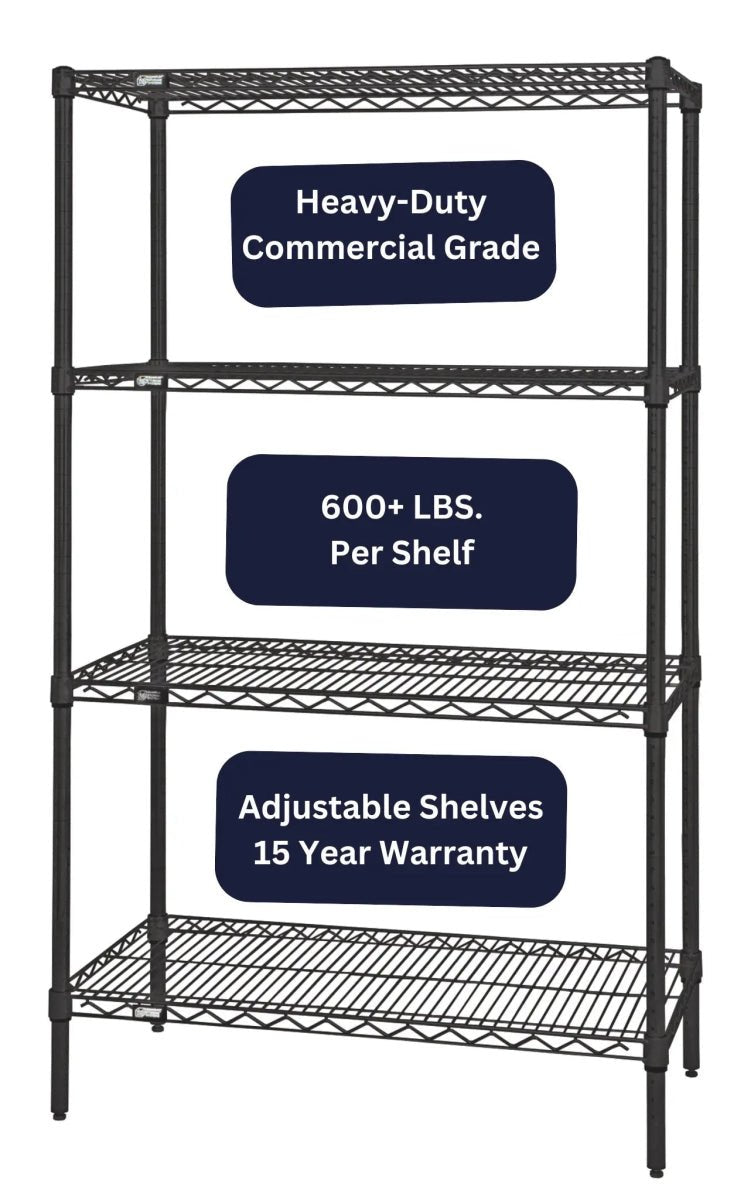

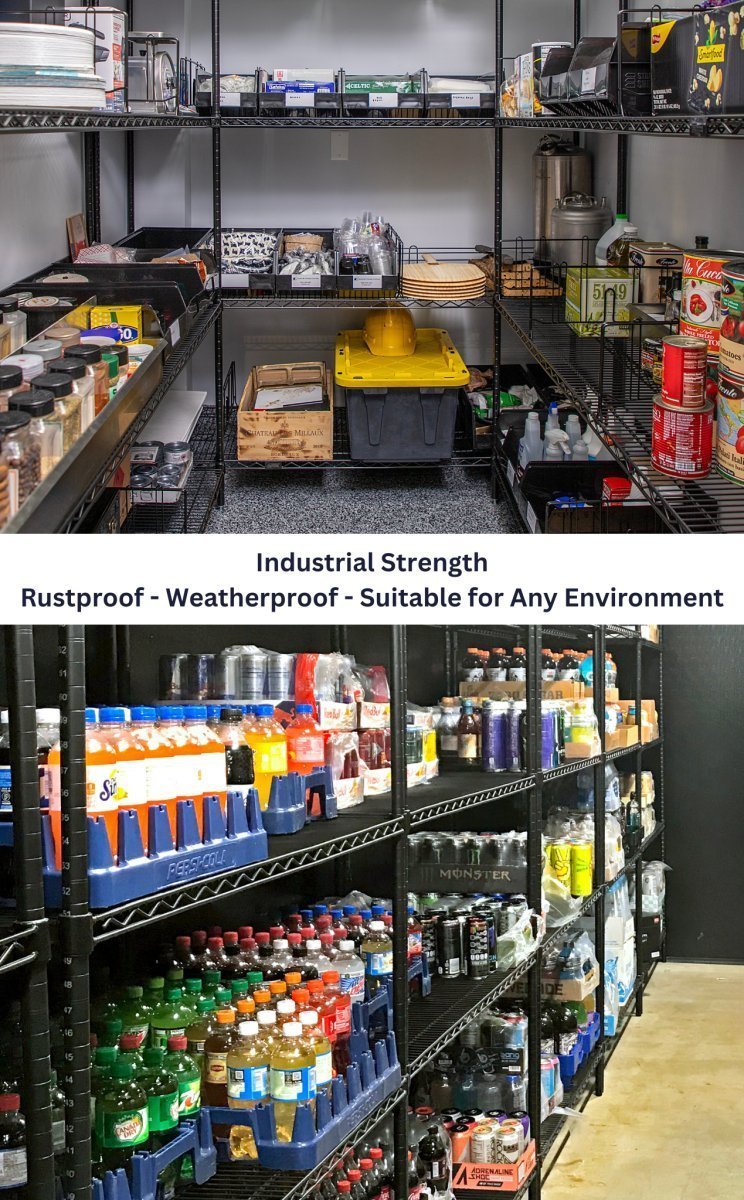

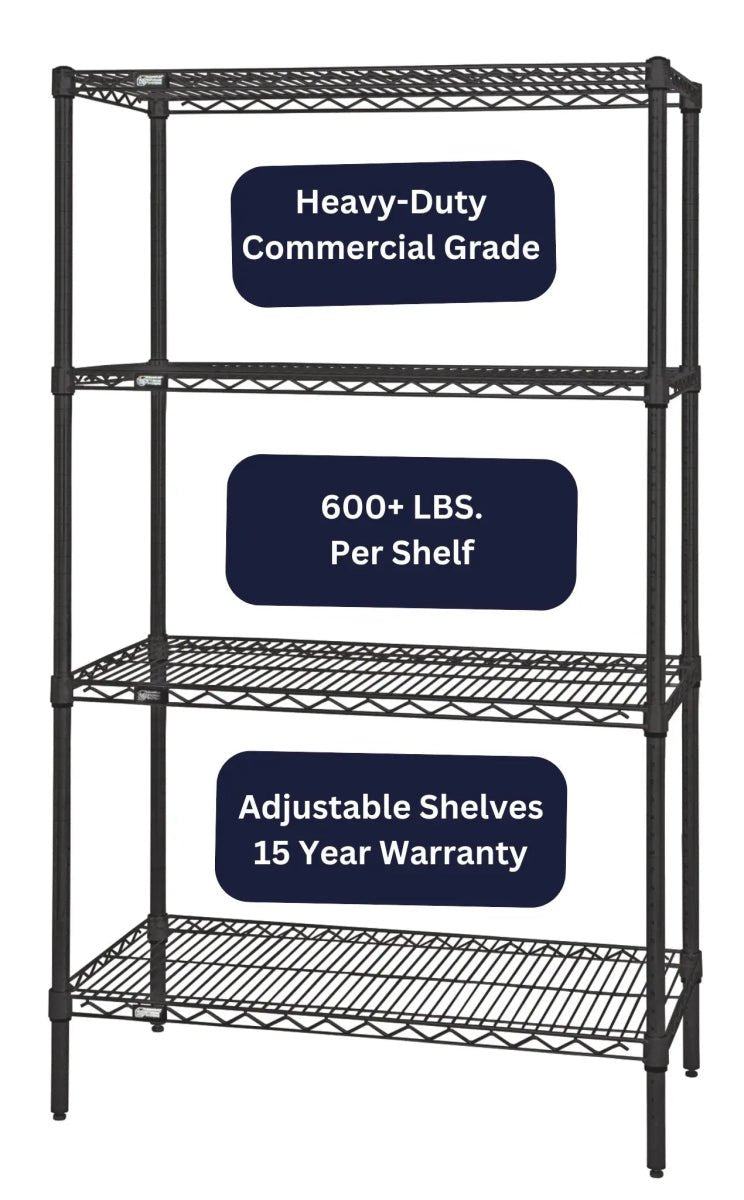

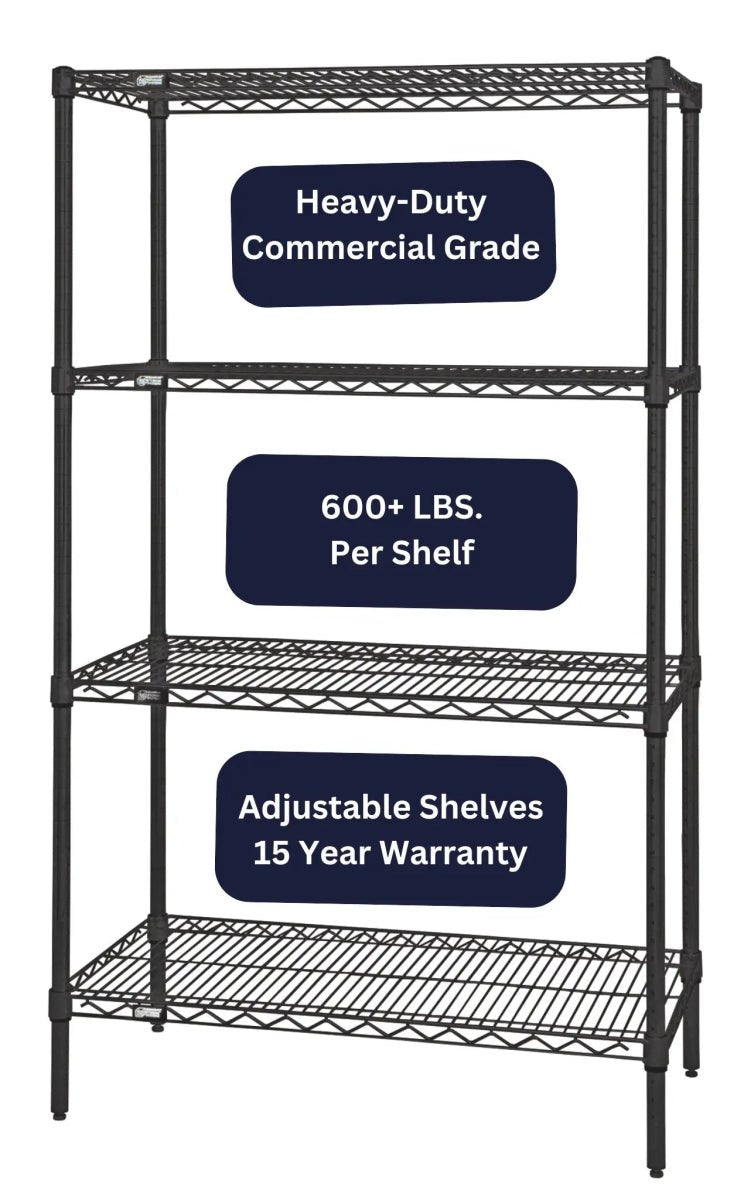

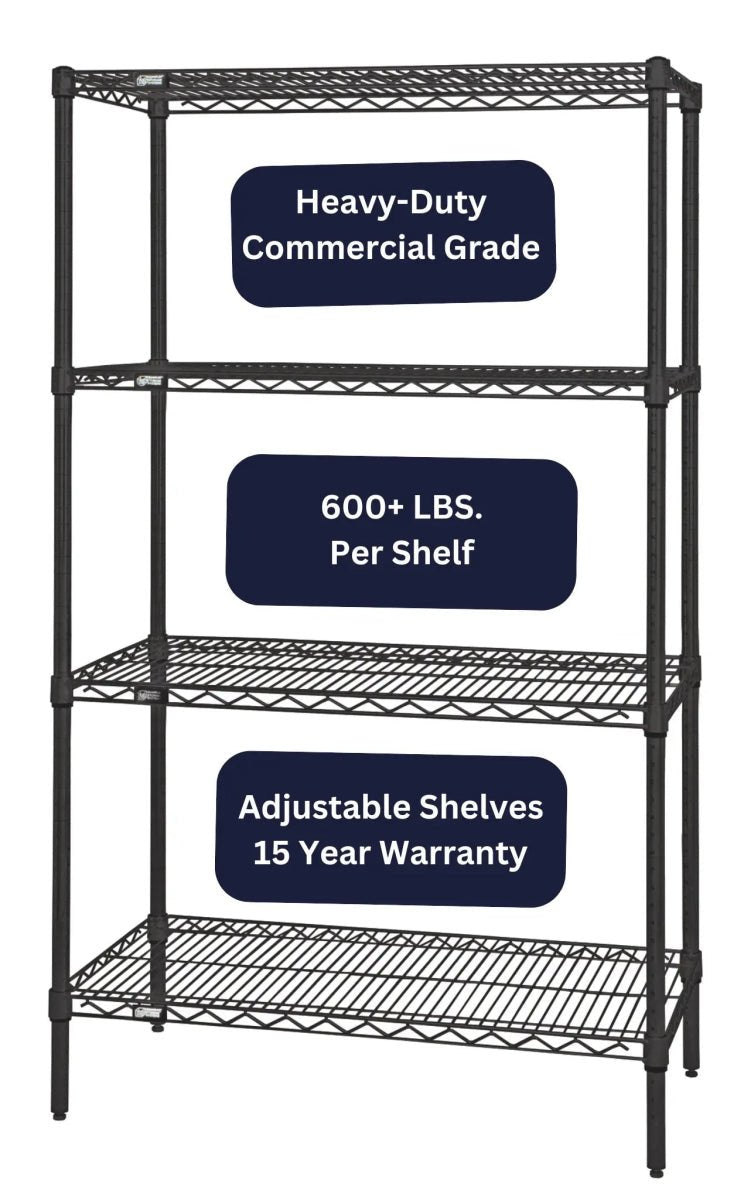

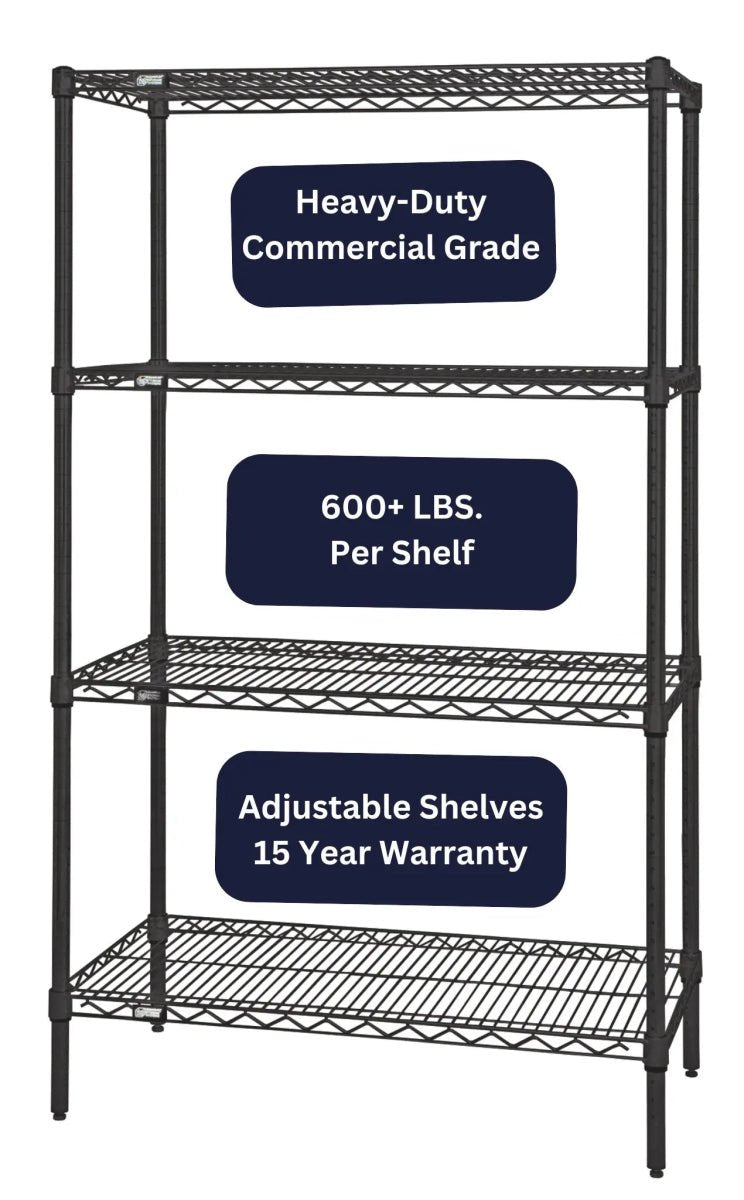

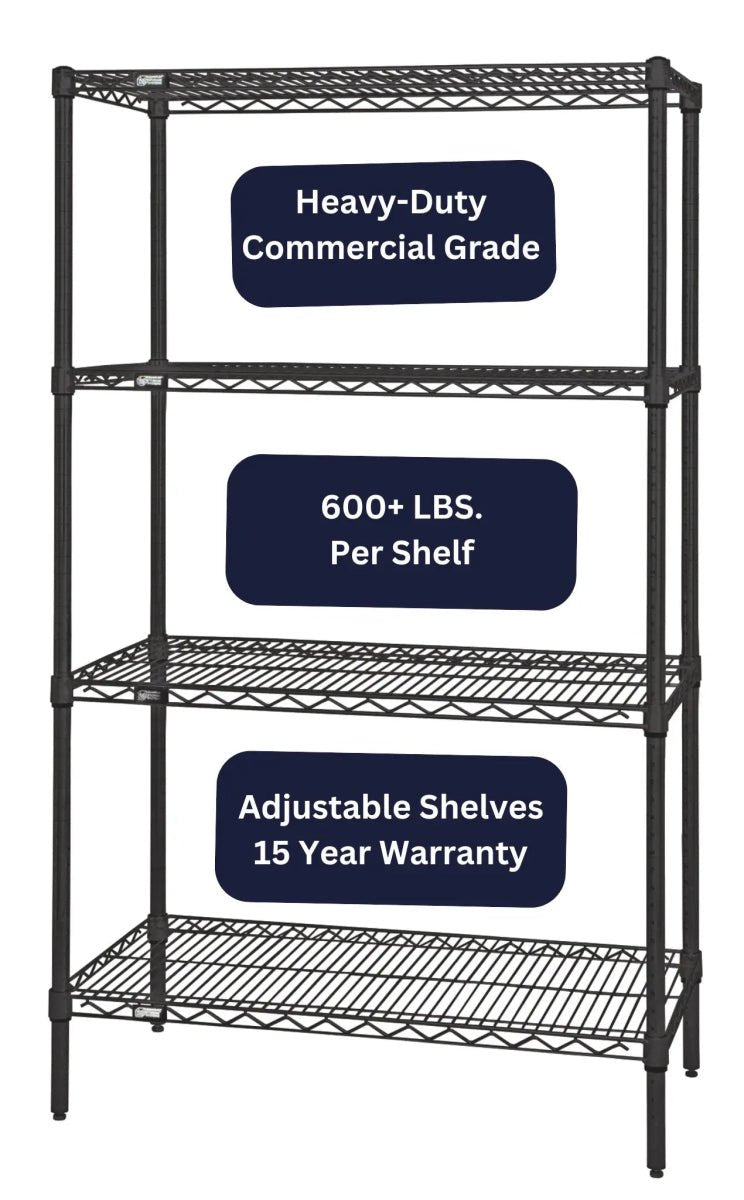

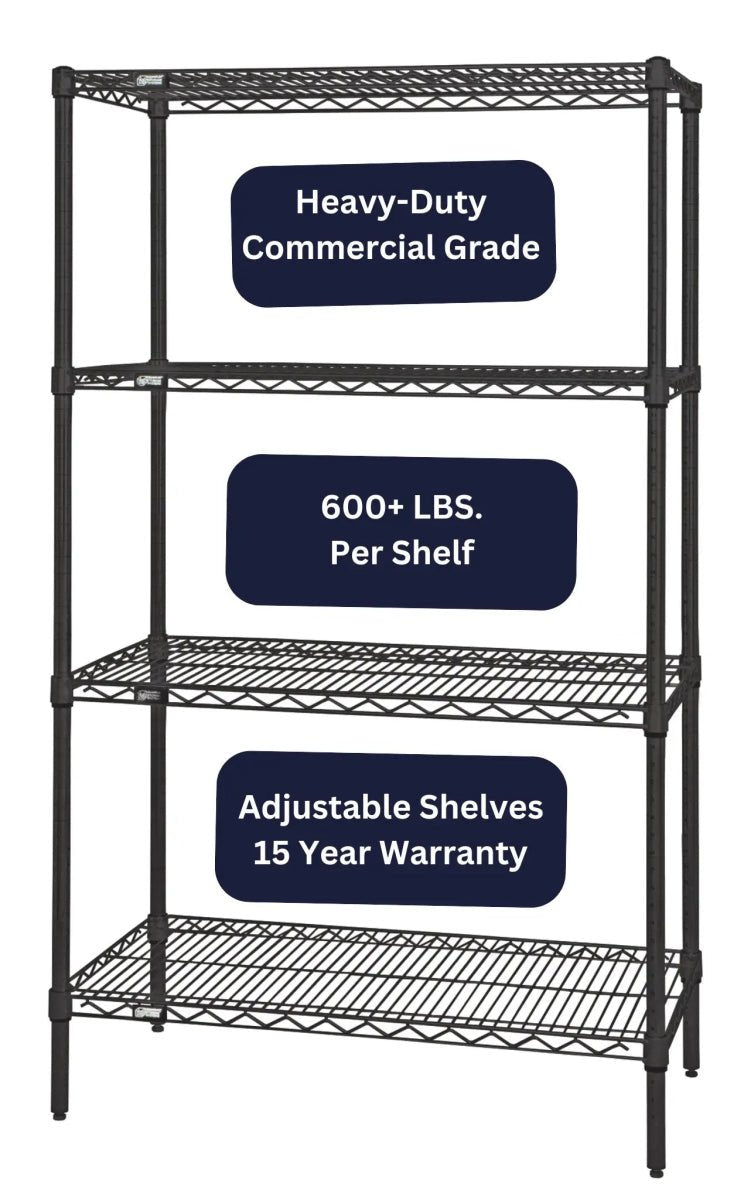

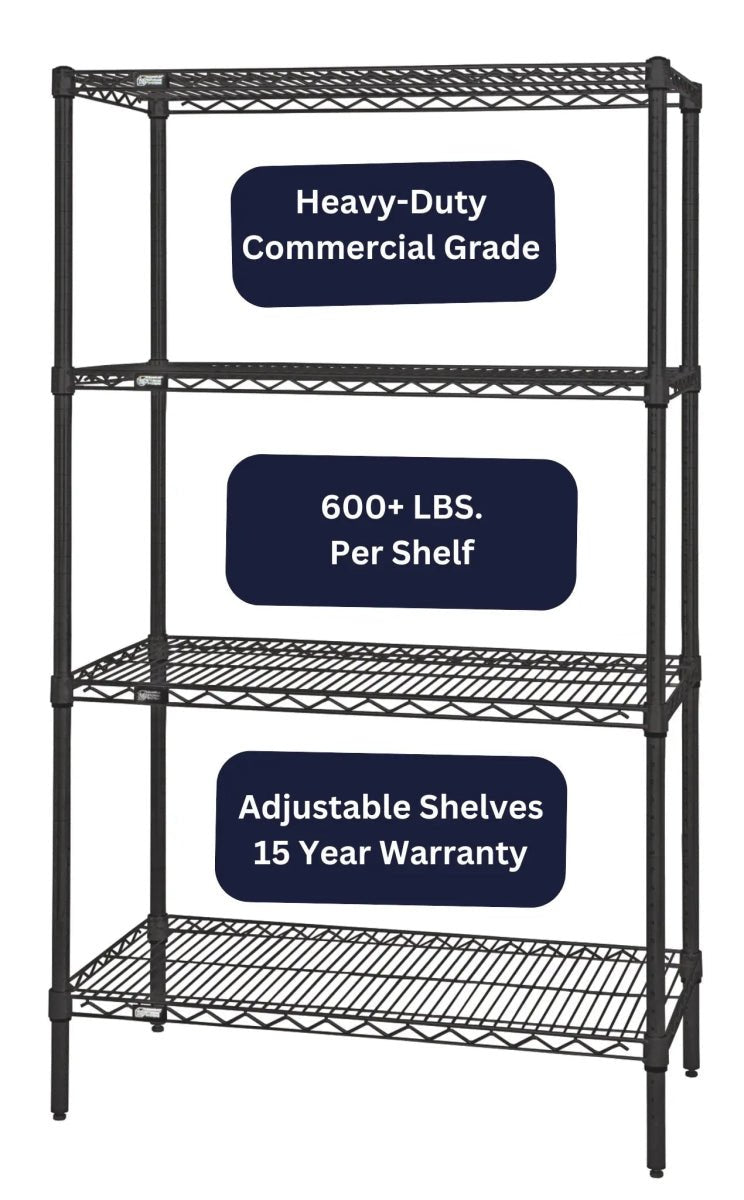

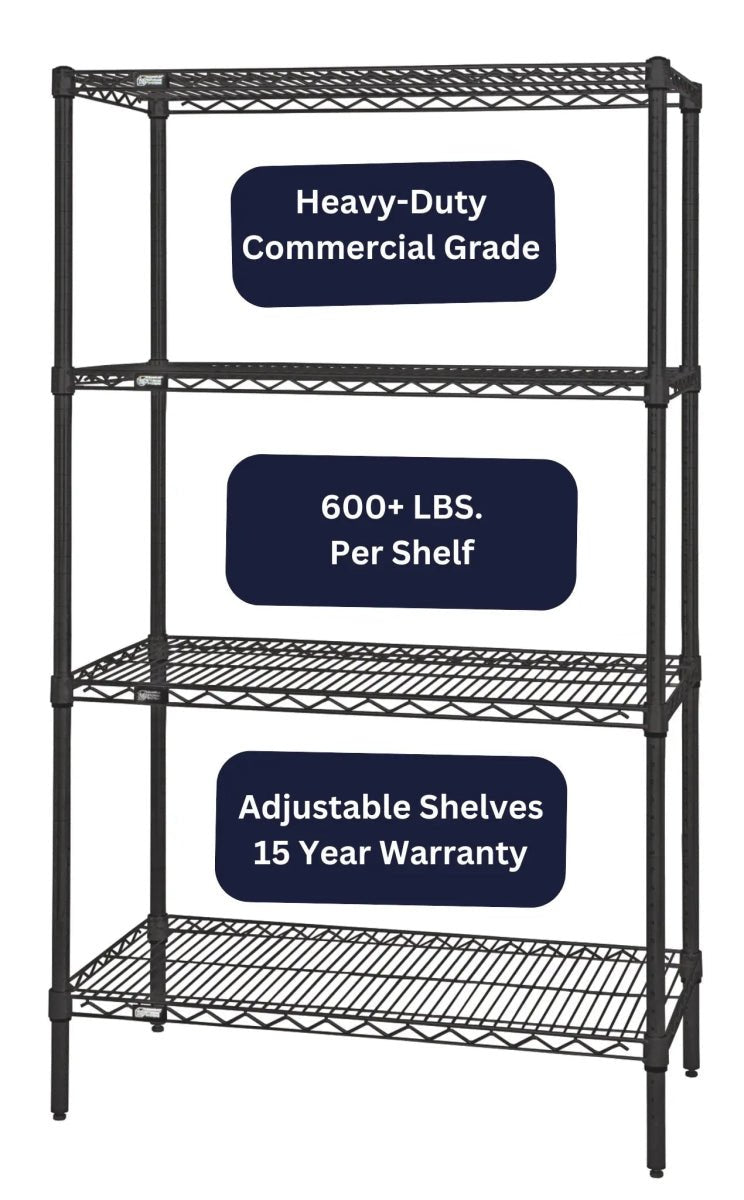

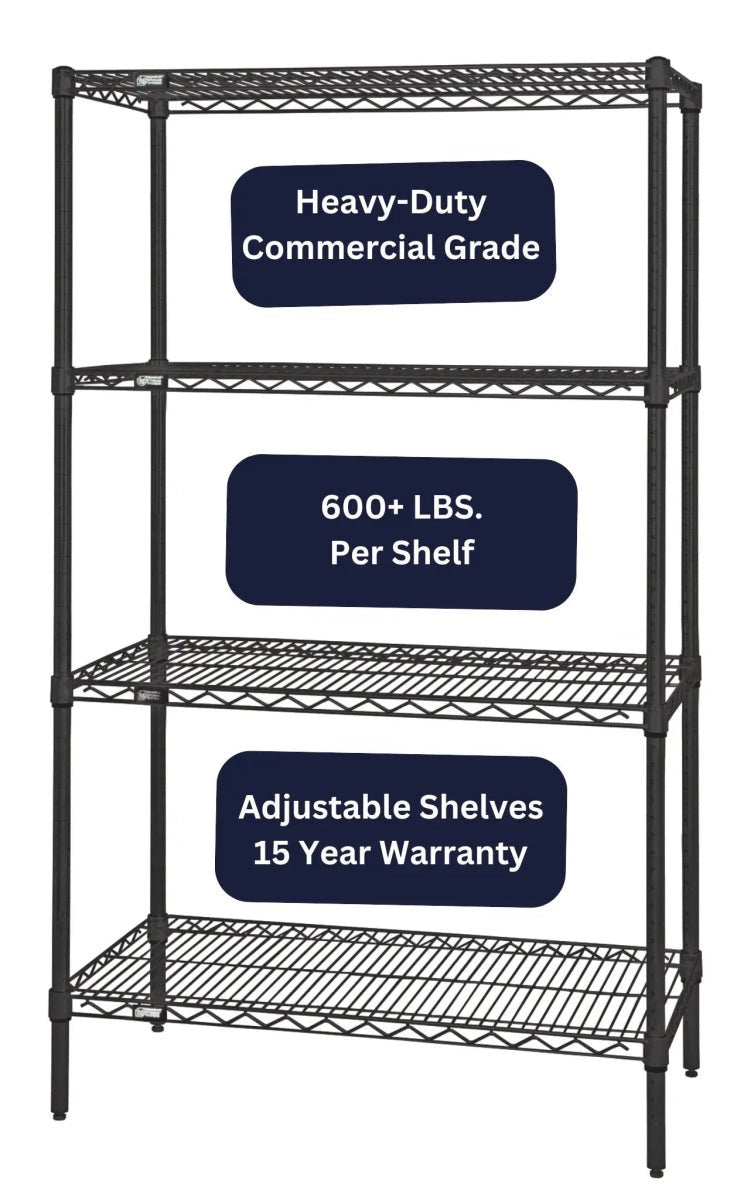

Epoxy coated wire shelving is our best selling of all shelving finishes. Available in black, green or gray, epoxy shelving is equally as heavy-duty as our other finishes, but comes at a lower price. Additionally, epoxy coated wire shelves have more utility and functionality than most other finishes, since they are suitable for both wet or dry applications and carry a 15 year warranty against rust, corrosion or bacteria build-up. Epoxy shelves are perfect for restaurants, walk-in coolers or freezers, greenhouses or any environment that is prone to moisture or humidity.

Showing 1 - 36 of 46 products

Display

View

Filters (0)

Epoxy Coated Wire Shelving

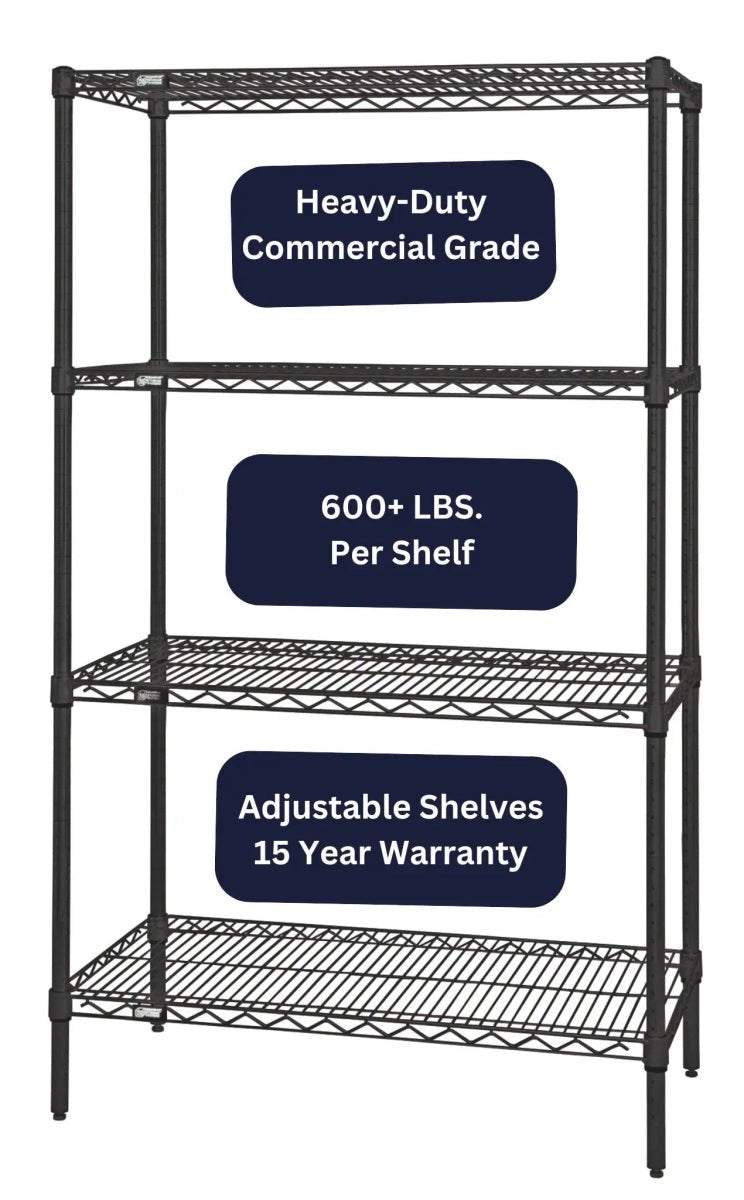

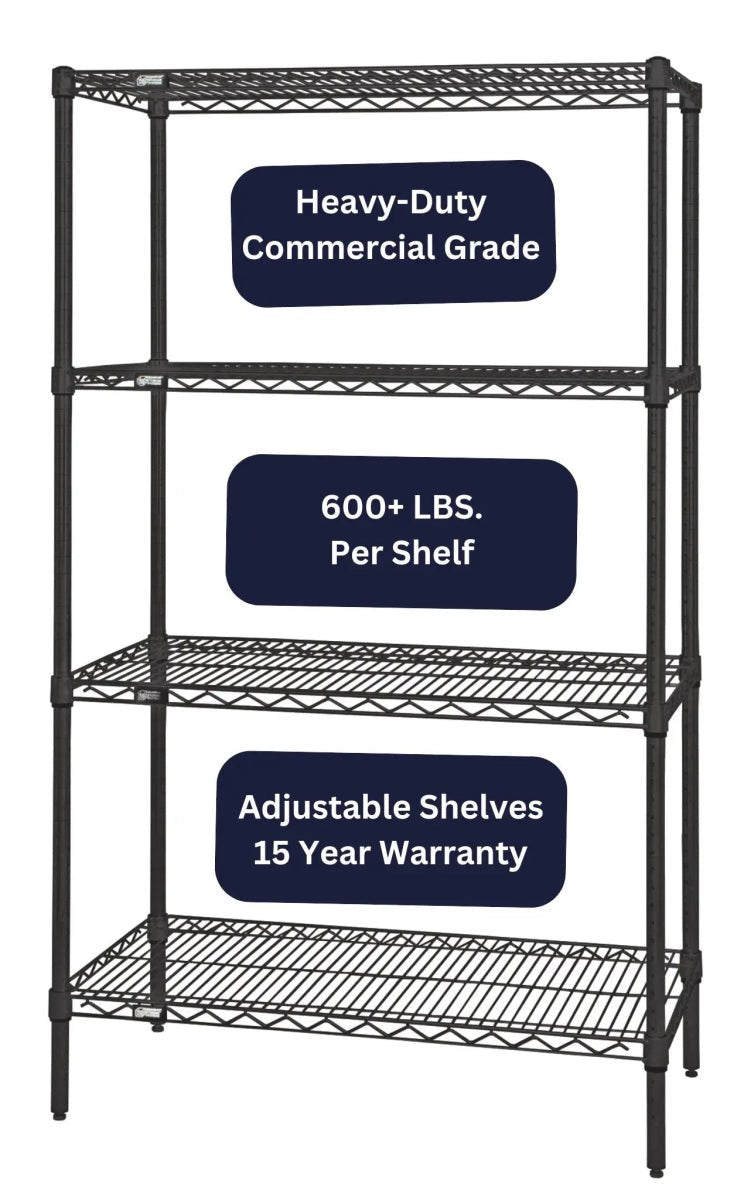

Antimicrobial, epoxy coated wire shelving is ideal for wet or humid settings where you are looking to protect against rust, corrosion and bacteria buildup. Backed by a 15-year warranty, epoxy coated wire shelving is extremely commonplace in commercial kitchens, hospitals, garages, and various other industrial settings. Epoxy wire shelving can hold from 600-800 lbs. per shelf and is easy to assemble without any tools. Some key advantages of epoxy coated shelving includes:

Corrosion Resistance: Epoxy coating adds a protective layer to the shelf that is resistant to mold, mildew and bacteria buildup. This makes the shelves suitable for wet environments, where standard chrome or plastic shelves would begin to rust and corrode. The epoxy coating is especially useful in environments where the shelves might come into contact with water or moisture, such as kitchens, walk-in freezers and coolers, garages, greenhouses, gardens or basements.

Chemical Resistance: Epoxy coated wire shelves are often exposed to acids, bases, solvents, cleaning agents, oils, greases, salts, brines, biological samples, disinfectants, sterilizing agents, and radiographic chemicals. Their ability to withstand these substances makes epoxy shelving ideal for use in settings like laboratories, hospitals, and industrial or automotive environments, where regular contact with such reactive and potentially corrosive materials is common.

Chemical Resistance: Epoxy coated wire shelves are often exposed to acids, bases, solvents, cleaning agents, oils, greases, salts, brines, biological samples, disinfectants, sterilizing agents, and radiographic chemicals. Their ability to withstand these substances makes epoxy shelving ideal for use in settings like laboratories, hospitals, and industrial or automotive environments, where regular contact with such reactive and potentially corrosive materials is common.

Aesthetic Appeal: Our epoxy coated wire shelving is available in three different color finishes; black, green and gray. We've got an option to match the decor of your location making them a great option for front-of-house storage in addition to back-of-house inventory management.

Cost-Effective: Despite its high performance, epoxy coated shelving tends to be cost-effective, offering a great balance of price and longevity.

Cost-Effective: Despite its high performance, epoxy coated shelving tends to be cost-effective, offering a great balance of price and longevity.