Freezer Safe Storage Bins

Recently viewed

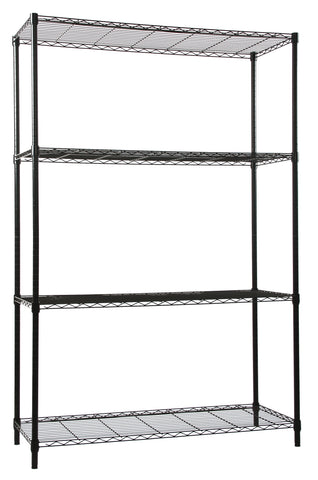

Walk-in Freezer and Walk-in Cooler Shelving Units

Walk-in freezers and coolers are a lot more commonplace than people realize. They are utilized in many industries, some obvious, and others not so obvious. Some of these industries include: food-service, food manufacturing/processing, healthcare, hospitality, biotech, agriculture and countless others. As we work with our customers in these industries, we are constantly asked to suggest some shelving solutions to help maintain organization and ensure items are secure and easy to be located.

The temperature range for a walk-in cooler is typically between 34° to 40°F, perfect for storing fruits, vegetables, dairy and other prepared foods. In a walk-in freezer, the temperature is typically below 0°F, ideal for keeping meats, seafood, vegetables and other items frozen. Shelves that are not specifically designed for use in walk-in coolers or freezers can experience several issues when placed in these cold environments, due to the extreme temperature and moisture conditions inside the cooler or freezer. The ability to withstand rust & corrosion is the #1 characteristic of any cooler or freezer shelving. The shelving used must be able to endure these low temperatures as well as high levels of moisture, to prevent the growth of harmful bacteria and keep food fresh.

With everything above in mind, there are three specific finishes that are suitable for walk-in freezers and walk-in coolers. Those include: epoxy-coated, stainless steel, and polymer/plastic, which we'll go into detail about below.

Epoxy-Coated Shelving: The most economical of the options, epoxy-coated wire shelves and poles are treated with a special coating to resist rust, corrosion, and bacteria build-up, making them ideal for high-moisture, cold environments like a walk-in freezer or walk-in cooler. The epoxy coating is electrostatically applied to carbon steel, and then is treated with a zinc phosphate. Epoxy coated wire shelves have a 15 year warranty against rust, corrosion or bacteria buildup.

For example, when a high-end steakhouse had trouble with rusting shelves, we successfully replaced them with epoxy-coated units to maintain their premium products' safety and quality.

This steakhouse stored their premium cuts of meat in a walk-in freezer. Unfortunately, their previous metal shelves started to rust due to the moist, cold conditions, threatening the quality of their steaks. We assisted them by replacing the standard, retail quality shelving with epoxy-coated, industrial shelving units that are specially designed to resist cold and moist conditions. This long-lasting, economical solution ensured their inventory was stored safely and hygienically, preserving their high-quality standards and preventing potential financial loss from spoiled meat. You can also view this case-study on TJ's Craft Beers for more info on epoxy shelving in restaurants.

Click here to view our epoxy-coated shelving units.

Stainless Steel Shelving: Exceptionally durable, rust-resistant stainless steel shelves can withstand both low temperatures and high moisture levels. Their smooth, non-porous surface is easy to clean, ensuring high hygiene standards.

For instance, a renowned seafood restaurant experiencing corrosion due to saltwater residue found the solution in our stainless steel shelves, preserving their seafood's quality and freshness.

At this renowned restaurant, their aluminum shelves in the walk-in cooler began corroding due to the saltwater residue from the seafood. This not only threatened the quality of their premium seafood but also posed potential food safety issues. We recommended transitioning to stainless steel shelving. Despite being more of an investment upfront, these shelves proved highly resistant to the cold, moisture, and saltwater conditions of their cooler. They were easy to clean, ensuring a hygienic storage environment for their seafood, which in turn preserved the restaurant's reputation for high-quality dishes. The lifetime warranty gave them peace of mind knowing they made a sound investment.

Click here to view our stainless steel shelving units.

Polymer Shelving: Polymer shelves, made from durable plastic, resist rust, corrosion, and impacts. An antimicrobial coating adds an extra layer of protection for high-hygiene environments. Their vented design promotes even cooling, and they are light enough for easy rearrangement.

A large hospital kitchen benefited from our polymer shelves when they needed to maintain consistent temperatures in their walk-in coolers.

The hospital was using solid metal shelving in their walk-in coolers, which obstructed airflow and caused temperature inconsistencies. This had potential implications for food safety. We helped them replace their existing shelves with lightweight, vented polymer shelving. The enhanced air circulation led to more consistent cooling, while the antimicrobial coating offered additional protection. Although polymer shelves can be a bit more expensive initially, they are a smart, long-term investment given their durability, ease of maintenance, and the critical importance of food safety in a hospital environment.

Click here to view our polymer shelving units.

Choosing the right type of shelving involves considering your specific needs and conditions. Whether you're running a high-end steakhouse, a bustling bakery, a renowned seafood restaurant, or a large hospital kitchen, we have a proven track record of providing optimal shelving solutions for walk-in freezers and walk-in coolers. Our expert advice can help you streamline operations, improve food safety, and contribute to the success of your business.

SUITABLE FOR ALL HIGH HUMIDITY ENVIRONMENTS

In addition to walk-in freezers and coolers, stainless steel, epoxy and polymer shelving are suitable for all high humidity environments. High humidity can cause a range of issues from food spoilage to the growth of mold and mildew. Below are examples of some locations that struggle with high humidity and have began to use our shelving solutions to combat this challenge:

Basements and Garages: In many homes, basements and garages are the go-to spots for extra storage. Unfortunately, these areas are often poorly ventilated and prone to dampness. Wooden shelves can warp or rot, and metal shelves may rust.

Commercial Warehouses: Warehouses, especially those in coastal or tropical regions, can face extreme humidity. This is problematic when storing sensitive items like electronics or perishable goods.

Greenhouses: While high humidity is beneficial for plants in greenhouses, it can be detrimental to shelving. Stainless steel or epoxy coated shelves are popular choices for greenhouses.

Boats and Marinas: In these inherently humid environments, shelving needs to withstand not just humidity but also saltwater corrosion. Marine-grade stainless steel or plastic polymer shelving is recommended.

Laundry Rooms: The constant use of washing machines and dryers in laundry rooms creates a humid environment. Shelving in these spaces should be made from materials that resist moisture.