How to Organize Components Before Assembly: Pre-Production Setup for Manufacturers

In manufacturing, success starts long before the first product comes off the line. Pre-production setup, the careful organization and staging of materials and components, plays a critical role in ensuring smooth operations, minimizing errors, and maintaining high standards of quality.

Whether you're assembling electronics, automotive parts, or industrial machinery, how you prepare your components can make or break your production efficiency.

Why Pre-Production Setup Matters

Fabrication involves shaping, cutting, assembling, and joining materials like metals, plastics, or composites to create finished parts or products. It’s a core step in manufacturing across industries including aerospace, automotive, construction, and electronics.

Organizing Parts for Quality & Efficiency

Maintaining strict quality control begins with segregating and labeling components. Separating parts by batch or lot number improves traceability, allowing manufacturers to:

- Track down defects to a specific batch

- Implement targeted recalls

- Prevent mixing of incompatible or defective parts

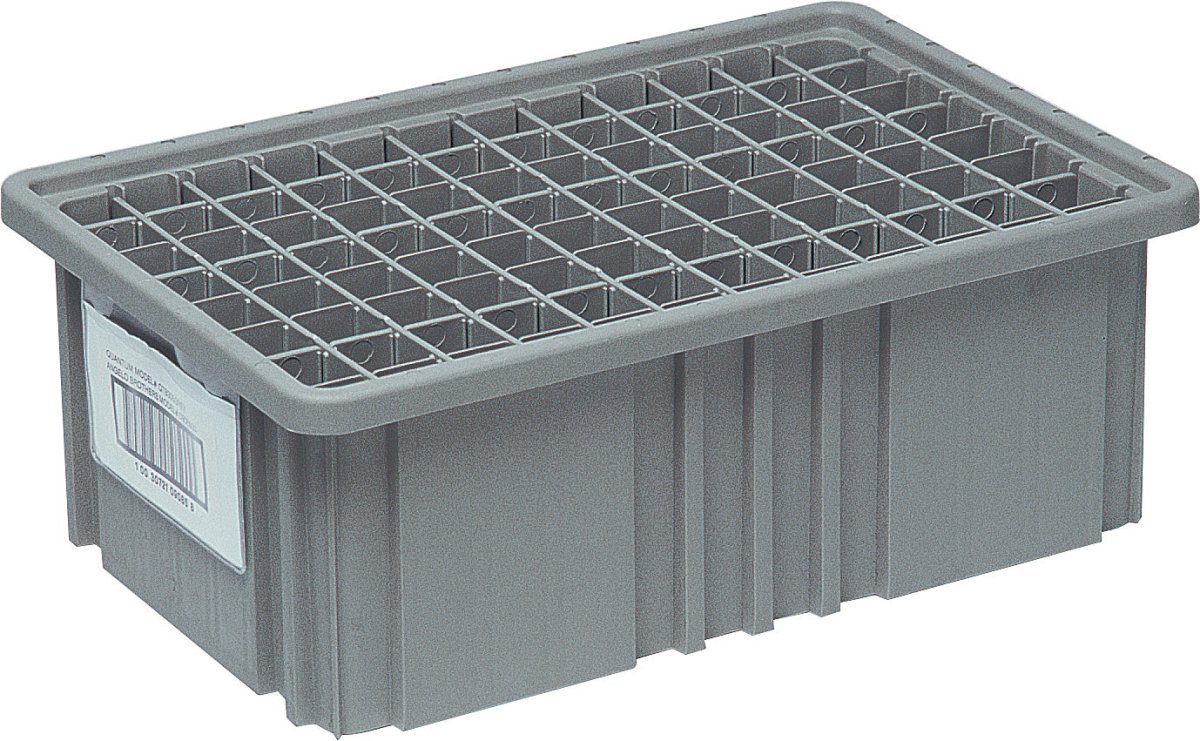

One of the most effective tools we’ve seen manufacturers use is the dividable grid container.

Dividable Grid Containers: The Smart Way to Stage Parts

These plastic containers use removable lengthwise and widthwise dividers to form customizable compartments inside each bin. Whether you need to separate 6, 24, or even 192 individual components, these containers offer a flexible and efficient solution.

Benefits of Dividable Grid Containers:

- Customizable layout – Adjust compartments to fit the size and quantity of your parts.

- Improved traceability – Keep batches clearly separated within the same container.

- Streamlined transitions – Move parts from inventory to quality control to the production floor without disrupting organization.

👉 See how many compartments each grid container can create

Production Phase: From Staging to Assembly Line

Once parts are staged, they’re moved to the production line in sync with the production schedule. This just-in-time delivery method ensures the right parts arrive at the right time—preventing delays and excess inventory buildup.

As components move from staging to production:

- Workers (or machines) can begin assembly with no sorting delays

- Any discrepancies in inventory are identified and corrected quickly

- Production stays lean, efficient, and accurate

The use of dividable containers throughout this process minimizes handling time and preserves order, ensuring that the line operates at peak performance with minimal downtime.

Final Thoughts: Invest in Pre-Production, Reap Long-Term Gains

Organizing your components before assembly may seem like a small detail, but it's a strategic move that supports lean manufacturing, quality assurance, and operational efficiency. Tools like dividable grid containers aren’t just storage—they’re essential to a well-oiled production system.

Related Resources for Manufacturers

- Automation Totes: Optimizing Material Handling in Automated Applications

- PCB Storage & Handling in Electronics Manufacturing

- Material Handling: What it is & Why it Matters

- Importance of ESD Safe Bins in Electronics Manufacturing

- Manufacturing and Assembly: Importance of Plastic Parts Bins

- EMS Storage & Handling