Protecting Your Sensitive Electronics: Choosing the Right ESD‑Safe Bins, Totes & Containers

Server boards, PCBs, and other SMT components are the nerve‑center of today’s data‑driven world, and nothing shortens their life faster than an unexpected electrostatic discharge (ESD). At Industrial 4 Less we stock a complete line of permanently conductive storage solutions that eliminate that risk while keeping your workspace organized and efficient.

Why ESD Control Matters

-

Invisible but destructive: A static charge you can’t feel (as low as 100 V) is enough to “zap” micro‑circuits.

-

Cumulative damage: Repeated micro‑shocks degrade signal integrity long before the part fails outright.

-

Regulatory & customer requirements: ISO/ANSI/IPC standards for electronics manufacturing call for documented ESD safeguards.

Our conductive polymer bins create a Faraday‑cage effect, dissipating static in < 0.1 second and holding a surface resistivity of < 10⁵ Ω/sq — all well inside MIL‑B‑81075B guidelines.

What Makes Our ESD‑Safe Bins and Containers Different

- Carbon‑filled copolymer polypropylene: Durable, chemically resistant, and virtually unbreakable—even under heavy loads.

- Permanently conductive: The anti‑static properties are built into the material, so they won’t wash away; bins can be cleaned with normal detergents.

- Made in the USA: Consistent quality and short lead‑times—every item leaves our warehouse within 24 hours.

- Free shipping & automatic volume discounts: Budget‑friendly for prototype labs and high‑volume production floors alike.

Product Spotlights & Best‑Fit Applications

1. Dividable Grid Containers (DG Series)

Perfect for server board assemblies, IC trays or mixed SMT reels that change from build to build.

-

Eight footprints, depths 2½"–12" for anything from DIMMs to graphics cards.

-

Snap‑in long and short dividers let you create 1 ⅛"‑wide cells on the fly.

-

Optional tight‑fitting lids lock in components during kitting or courier transport.

-

Use case: Stage pre‑programmed BIOS chips, VRMs and standoffs for a server‑box RMA line; dividers keep each BOM separate while the conductive walls handle static.

2. Stack & Hang Parts Bins (QUS Series)

Ideal next to SMT placement machines or on flow racks feeding manual assembly.

-

Sizes from 5 ⅜" × 4 ⅛" × 3" to a roomy 18" × 16 ½" × 11".

-

Rear molded lip lets each bin slide onto louvered panels or rail shelving; front label slot speeds ID.

-

Optional cross‑dividers snap in without tools (no exposed metal).

-

Use case: Color‑coded labels on QUS239CO bins hold different resistor values at an SMT rework station; operators pull parts without ever touching the conductive metal trays underneath.

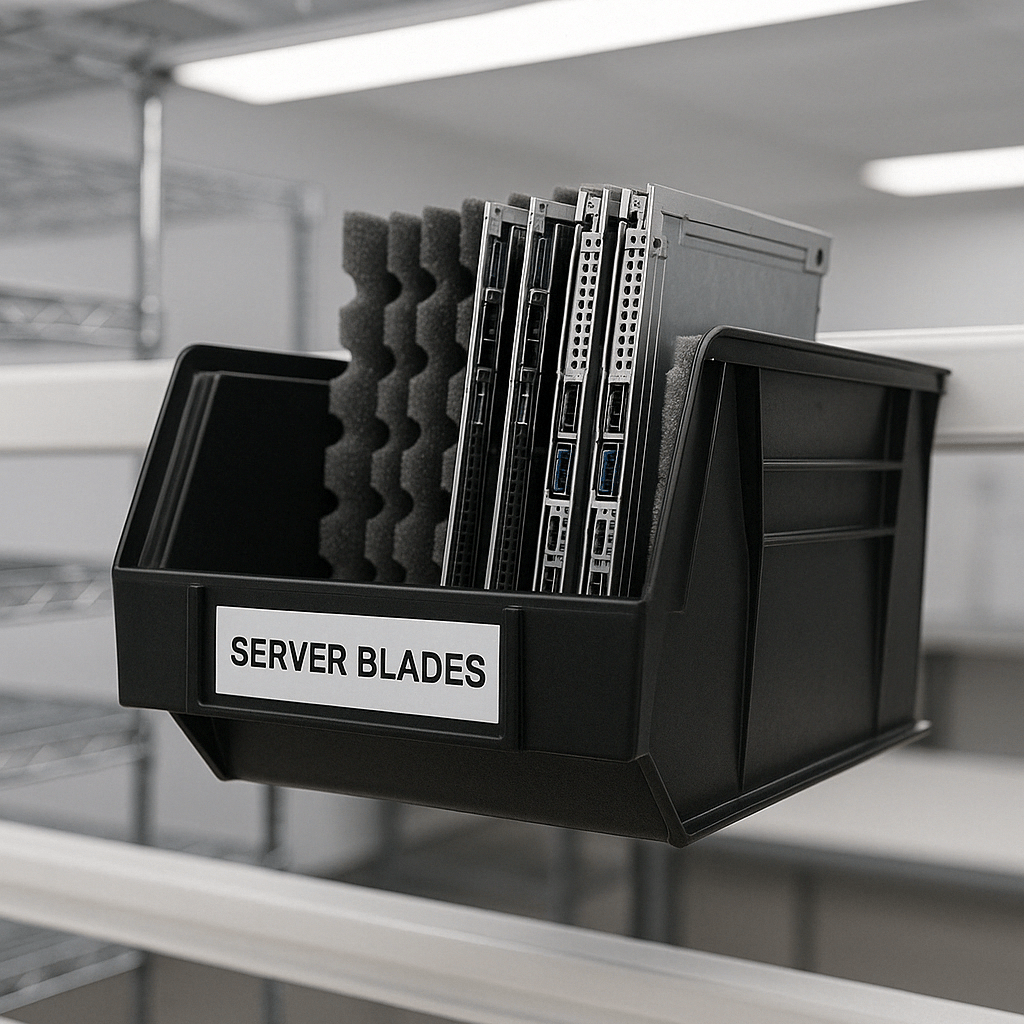

3. Nesting Shelf Bins (QSB Series)

When you need maximum density in fixed shelving—think secure stockrooms or automated vertical lift modules.

-

Footprints match 12", 18" and 24" shelf depths; front hoppers simplify pick‑and‑place.

-

Carton quantities (20–36 bins) keep per‑bin cost low for enterprise‑level deployments.

-

Use case: A cloud‑services data‑center keeps spare hot‑swappable server blades separated by rack ID. Labels on the QSB101CO bins match QR codes in their CMMS, so techs locate parts in seconds.

4. Reel Shelving with Conductive Rails

Need to store and feed ESD‑sensitive component reels? Our WRC‑R series reel racks accept 60-468 reels and arrive fitted with conductive uprights and rails, no separate ground straps required.

Storage & Transport Best Practices

Inside your facility

-

Maintain 40–60 % RH where possible; lower humidity increases static potential.

-

Place conductive mats on worktops and bond them (and your bins) to a common ground point.

-

Use barcoded labels plus bin model numbers (DG, QUS, QSB) to streamline MRP or ERP tracking.

Outbound or inter‑site shipping

-

Primary layer: Place each board inside a pink ESD bubble or moisture barrier bag.

-

Secondary layer: Pack the bagged board in a DG series container with lid or a stackable tote; use ESD foam or die‑cut inserts for shock absorption.

-

Tertiary layer: Seal the tote in a static‑shielding carton; mark the box “ESD Sensitive” and request climate‑controlled freight when temperature swings exceed 15 °C.

Proven Results

A Florida‑based contract manufacturer was losing nearly 12 % of RMA returns to latent ESD defects. After switching their kitting process to DG92050CO dividable containers and point‑of‑use QUS230CO bins, scrap fell to < 1 %, saving more than $37 k per quarter in rework labor and components—all while improving pick rates by 22 %.

Ready to Upgrade your ESD Storage Program?

Every conductive bin, tote, and shelf you see above ships free—usually same day—from Industrial 4 Less. Whether you’re protecting single‑board computers in a makerspace or thousands of 2U blades in a hyperscale data center, we have an in‑stock storage solution that meets your spec and your budget.

Explore the full collection of ESD‑safe options, or chat with our storage specialists for a one‑on‑one recommendation. Your components, and your customers, will thank you.