The Ultimate Guide to Epoxy Wire Shelving for Durability and Rust Resistance

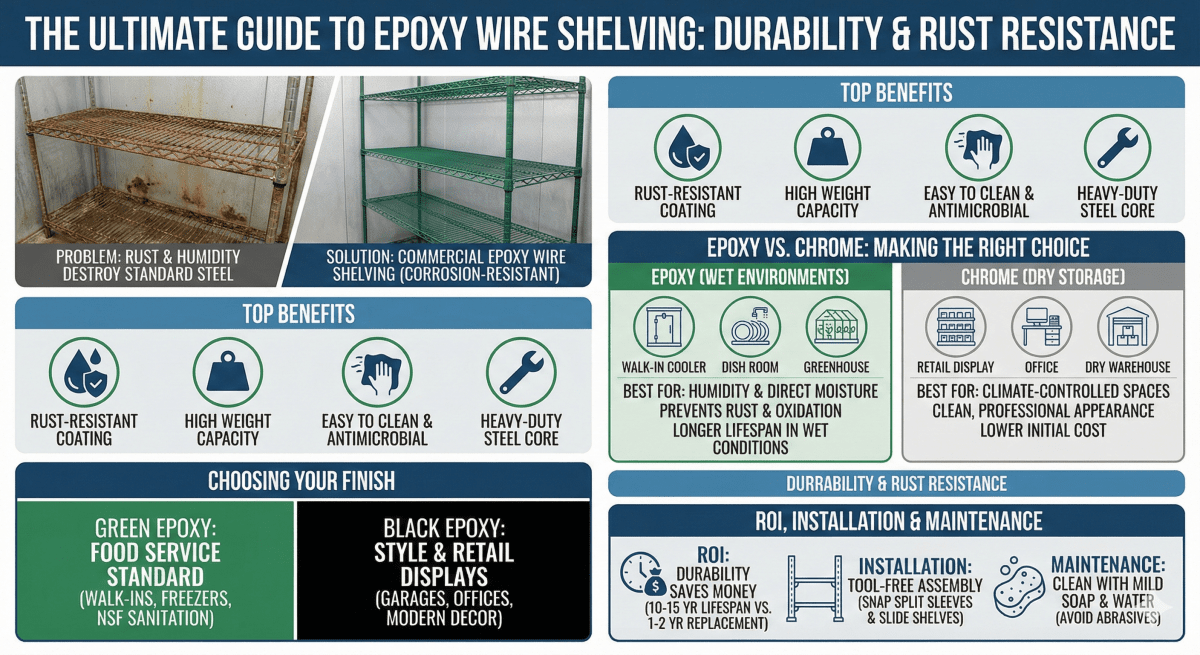

Humidity destroys standard steel shelves. Rust spreads fast and ruins inventory. Commercial epoxy wire shelving solves this with a corrosion-resistant coating. It withstands moisture in food service walk-ins, healthcare labs, and retail stockrooms. You get durable storage that stays clean.

Commercial epoxy wire shelving is a heavy-duty storage system constructed from carbon steel wire. Manufacturers coat this steel with a durable epoxy resin. This specific coating seals the metal completely, protecting it from air and moisture that cause rust and corrosion. You get distinct epoxy coated wire shelving benefits, particularly in humid or wet environments like walk-in coolers and dish rooms. Despite the protective layer, these units maintain high weight capacities suitable for commercial use. They handle the heavy loads required in food service, healthcare, and industrial warehousing without bending or failing.

Top Benefits of Epoxy Coated Wire Shelving

Epoxy shelving is built for conditions where standard chrome fails. Real Epoxy Coated Wire Shelving Benefits start with the protective coating baked over the steel wire. This creates Rust-Resistant Epoxy Shelving that withstands high humidity and direct moisture without corroding. It is the practical choice for walk-in coolers, commercial dishrooms, and greenhouses.

This durability makes Epoxy Wire Shelving for Wet Environments a smart investment because you replace units less often. Beyond rust, the coating resists weak acids and solvents that damage other finishes. For food service and healthcare, the smooth surface is easy to wipe down. Many epoxy coatings also include antimicrobial agents to stop bacteria growth between cleanings. If you need storage that handles moisture and chemicals, epoxy outlasts chrome. For dry storage, standard wire shelving works fine, but wet areas demand epoxy protection.

Making the Right Choice Between Epoxy Wire Shelving and Chrome

Your environment dictates the finish you need. Chrome works best in dry, climate-controlled spaces. It offers a clean appearance for retail displays or dry stockrooms. If you have a warehouse or office free from moisture, chrome wire shelving provides a professional look at a lower cost.

Humidity causes chrome to rust. If your shelving goes into a walk-in cooler, a dish room, or a damp basement, chrome fails. Epoxy is the correct solution for these wet areas. The coating seals the steel against oxidation and withstands constant exposure to moisture.

Apply this rule for Epoxy Wire Shelving vs Chrome: use chrome for dry storage and display. Switch to epoxy the moment water or humidity enters the space. This prevents rust and protects your investment. Epoxy shelving often undergoes rigorous salt spray testing, which also makes it the superior option for coastal facilities or areas with mild chemical exposure where chrome degrades immediately.

Choosing Your Finish: Green vs. Black Epoxy

Both green and black epoxy finishes defend against rust and corrosion. The difference lies in where you use them.

Green Epoxy Wire Shelving is standard for food service. You find this finish in walk-in coolers, freezers, and moist storage areas. It stands up to the damp conditions of a commercial kitchen and meets strict NSF standards for sanitation. If you store food in cold environments, this is your best option.

Black Epoxy Wire Shelving offers the same protection but focuses on style. It suits retail displays, home garages, and offices where you want a clean look. The finish hides dust and fits modern decor better than industrial chrome. Use green for wet storage and black for customer-facing areas.

The ROI of Epoxy: Why Durability Saves You Money

Focus on total cost of ownership rather than just the initial price. Installing standard chrome wire shelving in a humid walk-in cooler often leads to rust within 1 to 2 years. You end up replacing the same units repeatedly.

Epoxy coated shelving handles moisture without corroding. These units frequently maintain a useful shelving lifespan of 10 to 15 years in wet environments. While chrome costs less upfront, buying the same rack five times drains your capital.

Consider the operational costs as well. Replacing rusted shelving stops your workflow. Your team must unload inventory, tear down old racks, and assemble new ones. That downtime disrupts your facility. Choosing the correct material is a commercial storage investment that keeps your operation running and eliminates repetitive labor costs.

Installation and Maintenance Tips

Epoxy wire shelving installation takes only a few minutes. You do not need tools or professional help because the system uses split sleeves.

- Attach sleeves: Snap the plastic split sleeves onto the posts at your desired height until they click into the grooves.

- Add shelves: Slide the shelf collars down over the sleeves. Push firmly or tap with a rubber mallet to set them in place.

- Clean correctly: Wash surfaces with mild soap and water. Do not use abrasive scrubbers or steel wool. These damage the epoxy coating and lead to rust.

Conclusion

Epoxy stands as the best choice for wet, humid, or harsh storage environments. Assess your facility's humidity levels before purchasing to prevent premature corrosion. Browse the full catalog of epoxy wire shelving to find the right fit for your operation.