Order Picking Bins: The Ultimate Guide to Selection and Efficiency

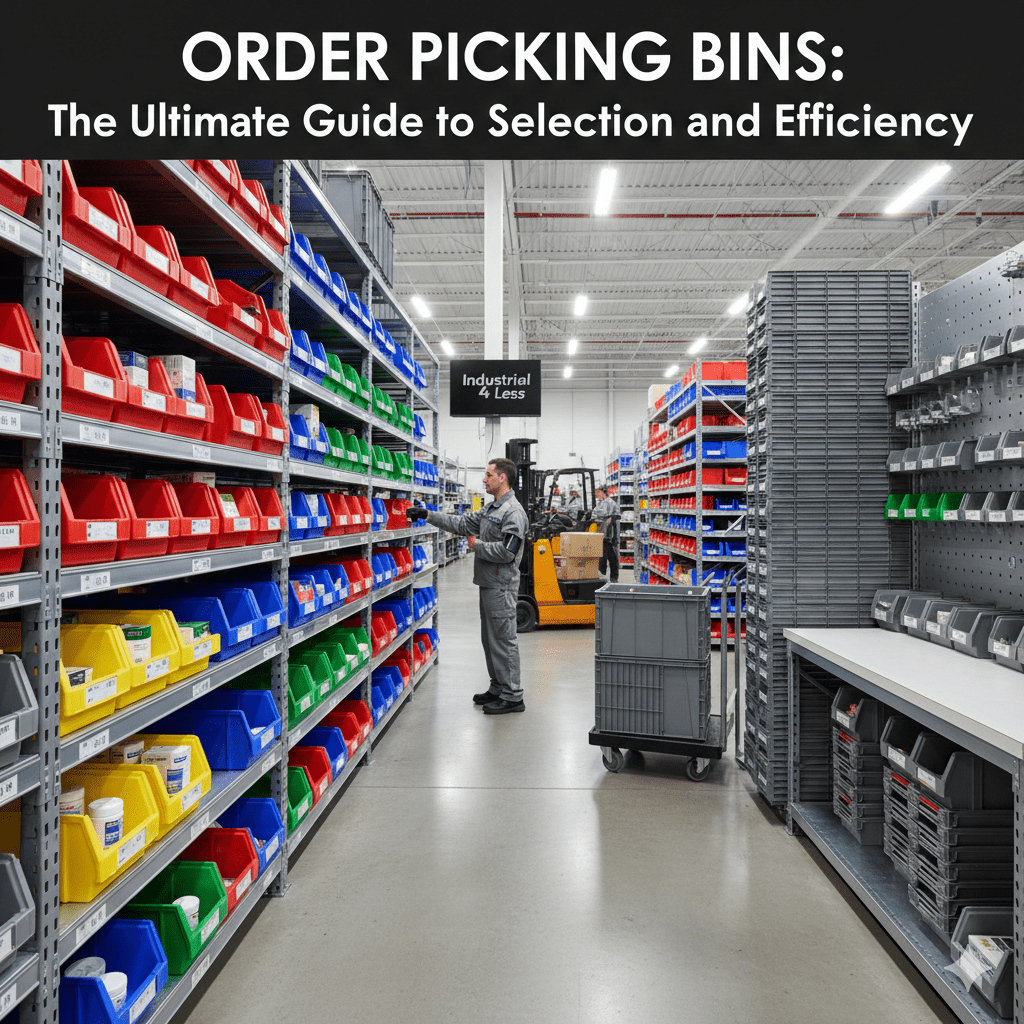

When pick rates drop or error rates climb, warehouse managers rarely blame the pickers, they blame the process. But process breakdowns often trace back to container systems that don't match picking methodology. For operations teams running multi-shift fulfillment environments, order picking bins aren't just storage, they're control points that determine pick speed, error rates, and labor efficiency across batch, zone, and discrete workflows.

The right bin system reduces pick time per line item, prevents mis-picks that trigger costly returns, and makes inventory accuracy visual without additional software. The wrong system creates pick face inconsistency, forces workarounds, and introduces variability that compounds across shifts.

This guide is written for warehouse managers, operations supervisors, and procurement teams actively standardizing picking infrastructure or expanding fulfillment capacity. We break down which bin types perform best for specific picking methodologies, how container selection affects measurable KPIs, and how to choose suppliers that support facility-wide deployment without introducing new problems.

Why Container Selection Directly Impacts Picking Performance

Generic storage, mismatched totes, damaged cardboard, or consumer-grade bins, introduces hesitation at the pick face. Hesitation equals lost throughput.

Purpose-built order picking bins create operational consistency:

- Reduced pick time per line item: Pickers don't search, dig, or manipulate containers to access inventory

- Lower mis-pick rates: Clear visual separation between SKUs prevents grabbing wrong items

- Improved space utilization: Consistent footprints and stackability maximize cubic storage without crushing inventory

- Better ergonomics: Proper bin design keeps items in the natural reach zone, reducing picker fatigue across long shifts

For operations leaders, the outcome is measurable: fewer picking errors, faster order cycle times, and tighter control over labor efficiency per line item picked.

Ready to standardize your picking infrastructure? Browse our complete selection of warehouse-grade picking bins designed for multi-shift operations.

Matching Bins to Your Picking Methodology

Container selection fails when it ignores actual workflow. A bin optimized for discrete picking slows down batch operations. The right order picking bins align with your specific methodology, not the other way around.

Batch Picking

Workflow: Pickers consolidate inventory for multiple orders simultaneously, then sort downstream.

Container requirements:

- Higher volume capacity to hold consolidated picks

- Mobile or cart-mountable for travel with picker

- Clear visual access to prevent mixing SKUs during consolidation

Use: Large-capacity open-front bins on mobile carts or totes with dividers for multi-SKU batches.

Avoid: Small fixed bins that force mid-pick returns to restock.

Zone Picking

Workflow: Inventory divided into distinct areas. Pickers stay within assigned zones and pass orders between zones.

Container requirements:

- Static placement on fixed shelving

- Color coding to visually define zone boundaries

- Consistent sizing for layout predictability

Use: Color-coded stackable bins or wall-mounted hanging bins that create visual zone separation.

Avoid: Uniform colors that blur zone boundaries and increase crossover errors.

Discrete Picking

Workflow: One order picked at a time, start to finish, by a single picker.

Container requirements:

- Maximum visibility for fast SKU confirmation

- Immediate hand access without container manipulation

- Optimal placement on static racking at pick height

Use: Open-front hopper bins on standard warehouse shelving for instant access to single SKUs.

Avoid: Deep bins or closed containers that add seconds per pick through lid/flap manipulation.

Order Picking Bin Types (and When to Use Each)

Different fulfillment environments require different container strategies. Choosing the right bin means matching container design to picking frequency, inventory type, and space constraints, not aesthetics.

Open-Front Hopper Bins

Use when:

- Discrete or zone picking with 50+ picks per hour per picker

- SKU verification must happen visually before pick

- Bins remain stationary on fixed shelving or louvered panels

- Pick accuracy is critical and mis-picks are costly

Angled or cut-down front provides immediate visual confirmation and hand access without removing the container. Reduces pick time per line item by eliminating lid removal or flap manipulation. Ideal for high-velocity SKUs in static pick faces.

Avoid when: inventory requires dust protection or batch picking demands mobile containers that travel with pickers.

Stackable Pick Bins

Use when:

- Floor or bench space is limited

- Vertical storage density is required without additional racking

- Workstations need self-contained picking walls

- Temporary or seasonal picking zones must scale quickly

Interlocking design allows bins to stack securely without shelving infrastructure. Creates standalone picking walls on workbenches or floor space. Useful for assembly kitting stations or overflow storage during peak seasons.

Avoid when: frequent restocking requires access to lower bins in the stack, forcing constant destacking.

Nestable Bins

Use when:

- Empty containers must return to central storage or cross-dock

- Available storage space for unused bins is limited

- Containers move between facilities or departments regularly

- Transportation costs for empty containers are a factor

When empty, bins nest inside one another to reduce storage volume by up to 70%. Saves space during return transit and when storing unused containers between seasonal peaks.

Avoid when: bins remain permanently stationed at pick faces and never return to storage.

Hanging Bins

Use when:

- Bench or floor space must remain clear for packing operations

- Small parts or hardware require organized, eye-level access

- Louvered panel or rail systems are already installed

- Pick faces need maximum density in minimal square footage

Rear mounting lip allows bins to hang on louvered panels or rail systems, positioning inventory at eye level while keeping work surfaces clear. Maximizes pick face density in tight spaces.

Avoid when: inventory weight exceeds panel load rating or items are too large for wall-mounted storage.

Material Selection: Plastic vs. Corrugated

Heavy-Duty Plastic Bins

Use when:

- Bins support metal parts, tools, or hardware over 10 lbs

- Multi-shift operations require impact resistance

- Containers will be reused for 3+ years

- Cleaning or sanitation is required

Industrial-grade polypropylene resists daily picker impact, supports heavy loads without deformation, and withstands wash-down in food-grade or pharmaceutical environments.

Avoid when: budget constraints exist and inventory consists of lightweight, non-abrasive items under 5 lbs.

Corrugated Plastic (Correx) or Cardboard

Use when:

- Budget is constrained and inventory turnover is high

- Bins hold lightweight items under 5 lbs

- Single-season or temporary use is expected

- Disposal after use is simpler than return logistics

Lower upfront cost makes corrugated options viable for short-term projects or low-impact environments.

Avoid when: bins will face daily picker impact, support heavy loads, or require multi-year service life.

Where Order Picking Systems Commonly Fail

Many facilities encounter performance problems not from poor picking processes, but from mismatched container infrastructure:

- Mixed bin sizing: Inconsistent footprints cause layout drift as inventory changes, forcing constant reconfiguration

- Consumer-grade containers: Bins crack or deform under daily picker impact, creating safety hazards and forcing emergency replacements

- No SKU standardization: Vendor discontinues bin models, making replacement orders complicated and causing pick face inconsistency

- Missing label infrastructure: Taped-on barcodes peel during handling, causing scan failures and manual entry delays

- Incompatible dimensions: Bins don't fit existing racking without adapters, wasting shelf depth or requiring infrastructure changes

- No visual replenishment signals: Opaque or deep bins hide inventory levels, causing stockouts at the pick face

Standardizing on warehouse-grade bins with consistent dimensions and built-in label infrastructure eliminates these failure points before they impact fulfillment.

Avoid these costly mistakes. Shop warehouse-grade bins with consistent SKUs for reliable replacement ordering.

How to Choose Order Picking Bins (and Suppliers)

Before standardizing bins facility-wide or across multiple zones, use this checklist to filter both products and vendors:

Load Capacity

Verify rated strength matches your heaviest SKU per bin. Overloaded containers fail mid-shift and create safety risks. Require published weight ratings, not vague "heavy-duty" claims.

Material Grade

Ensure warehouse-grade polymers designed for multi-shift operations, not consumer plastics that crack under impact. Ask for material specifications (polypropylene grade, UV resistance, impact ratings).

SKU Consistency

Confirm bins remain stocked for replacement orders 2-3 years from now. Vendor discontinuations force layout changes and create pick face inconsistency. Ask about SKU lifecycle and minimum stocking commitments.

Racking Compatibility

Verify dimensions fit existing shelving, louvered panels, or flow racks without adapters or modifications. Measure shelf depth, width, and weight capacity before ordering. Request sample bins for physical fit testing.

Label Infrastructure

Built-in label holders or card slots that support barcode scanners at pick height without peeling adhesive labels. Holders must accommodate standard label sizes (e.g., 3" x 5") and remain secure during daily handling.

Supplier Fulfillment Reliability

Vendor must deliver bulk orders (500-1000+ units) without backorders or split shipments. Delayed deployments stall facility-wide standardization and force mixed container systems during transition.

Divider Compatibility

If multi-SKU bins are required, verify dividers are available, fit securely, and don't reduce usable capacity excessively. Test divider stability under normal picking motion.

The goal is not just to buy bins, it's to deploy a standardized system that scales across zones without introducing operational variability.

Optimizing Bin Layout for Maximum Efficiency

Once bins are selected, placement strategy determines how effectively they support picking performance.

Golden Zone Prioritization

Position highest-velocity SKUs between waist and shoulder height (28"-60" from floor). This keeps frequently picked items in the natural reach zone, reducing picker fatigue and minimizing pick time per line item. Reserve lower shelves for slower-moving inventory and top shelves for overflow storage.

Color Coding for Zone Definition

Assign bin colors to picking zones or inventory categories. Red bins for Zone A, blue for Zone B, green for hazmat items. Visual differentiation prevents zone crossover errors and helps pickers identify priority stock instantly without reading labels.

Angle Bins for Visibility

Tilt open-front bins downward 15-20 degrees when mounting on louvered panels or angled shelving. Improved sight lines allow pickers to confirm SKU and quantity without reaching into bins, reducing pick time and mis-picks.

Install Dividers for Multi-SKU Control

Use removable dividers to separate similar parts within single bins. Prevents mixing during restocking and ensures pickers grab correct items without sorting. Particularly critical for fasteners, small hardware, or SKUs with similar appearance.

Schedule Regular Cleaning

Dust and debris accumulate in active pick faces. Schedule bin cleaning during shift changes or low-volume periods to prevent contamination transfer to inventory. Clean bins maintain product quality and prevent customer complaints from dirty packaging.

Pick Faster. Ship Cleaner. Standardize Once.

The right order picking bins reduce pick time per line item, prevent mis-picks that trigger return processing costs, and make inventory accuracy visual without additional software. When container systems match picking methodology, fulfillment runs predictably, and predictability protects margins.

Mismatched bins introduce hesitation at the pick face. Hesitation compounds across thousands of picks per shift. Worn-out cardboard and consumer-grade totes force workarounds that create variability, slow training, and increase error rates.

If you're standardizing bins across zones, expanding fulfillment capacity, or replacing a mixed container system, Industrial 4 Less stocks warehouse-grade picking bins designed for multi-shift operations. We support bulk deployments, maintain consistent SKUs for ongoing replacement orders, and deliver reliable fulfillment so your pick faces stay operational without supply interruptions.

Find the bins that match your workflow, and stop letting container problems slow down fulfillment.

Ready to Standardize Your Picking Infrastructure?

Questions about bulk orders or facility-wide deployment? Contact our team for volume pricing and technical support.